The intake manifold is a vital component in an engine, significantly impacting its performance and efficiency. In this guide, readers will delve into the intricate world of intake manifold connections, understanding their role in optimizing engine function. The blog will unravel the basics of intake manifold structure, materials used, common issues faced, and even present a practical case study for real-world application. By the end of this guide, beginners will have a solid grasp of how High Performance Intake Manifold works and their importance in the automotive realm. Additionally, a detailed diagram intake manifold will be provided to visually aid in understanding the complex connections and components involved.

Understanding the Intake Manifold

What is an Intake Manifold?

Definition and basic function

The Intake Manifold serves as a crucial component in an engine, responsible for distributing air to the engine cylinders. It ensures that the right amount of air reaches each cylinder for optimal combustion, enhancing engine performance.

Historical context and evolution

Throughout history, the Intake Manifold has undergone significant advancements to improve engine efficiency. Innovations in design have led to better airflow dynamics and enhanced fuel mixture processes, contributing to the overall evolution of intake manifold technology.

Key Components of an Intake Manifold

Plenum

The Plenum in an Intake Manifold acts as a central chamber that collects incoming air before distributing it to the individual cylinders. It plays a vital role in ensuring equal airflow to all cylinders, promoting balanced combustion.

Runners

Runners are individual tubes extending from the plenum to each intake port on the cylinder head. These channels guide the airflow from the plenum to the cylinders, optimizing air distribution and fuel efficiency within the engine.

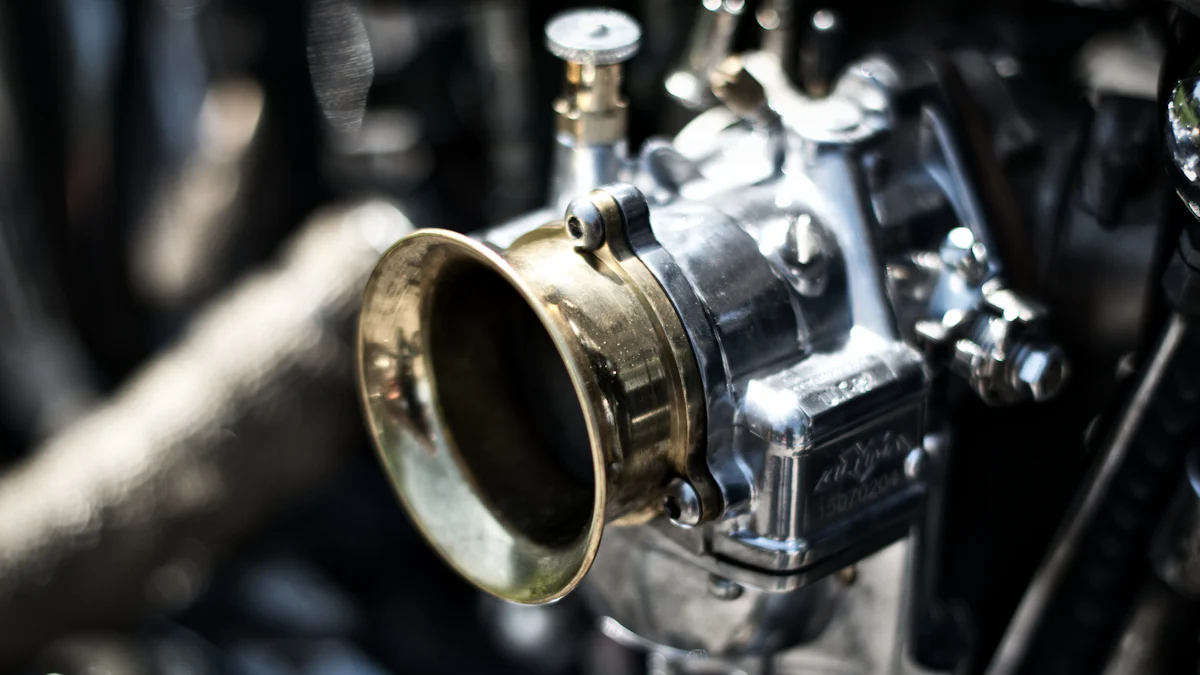

Throttle body

The Throttle body regulates the amount of air entering the engine by controlling the throttle plate’s position. This component directly influences engine power output and responsiveness based on driver input, making it a critical part of the intake system.

How the Intake Manifold Works

Airflow dynamics

The intricate design of an Intake Manifold facilitates smooth airflow dynamics within the engine. By carefully directing air through the plenum and runners, turbulence is minimized, ensuring efficient combustion and maximum power output.

Fuel mixture process

In conjunction with delivering air, the Intake Manifold also plays a key role in mixing fuel with incoming air. This process occurs within the intake system before reaching the combustion chambers, where a balanced air-fuel ratio is essential for optimal engine performance.

Materials Used in Intake Manifolds

Common Materials

Aluminum

- Aluminum is a popular choice for inlet manifolds due to its lightweight nature and excellent heat dissipation properties.

- It offers durability and reliability, making it a preferred material for high-performance cars.

- The use of aluminum in intake manifolds contributes to improved fuel efficiency and overall engine performance.

Plastic/Composite

- Plastic/Composite materials are commonly utilized in manufacturing inlet manifolds for various cars.

- These materials provide a cost-effective solution while offering sufficient durability for everyday driving needs.

- The lightweight nature of plastic/composite manifolds aids in reducing the overall weight of the vehicle, enhancing fuel economy.

Cast Iron

- Cast Iron has been historically used in traditional inlet manifolds, known for its robustness and longevity.

- While heavier compared to other materials, cast iron offers exceptional heat retention properties, ideal for certain engine configurations.

- The use of cast iron in modern intake manifolds provides stability and endurance under challenging operating conditions.

Pros and Cons of Each Material

Durability

- The durability of an intake manifold, whether made from aluminum, plastic/composite, or cast iron, is crucial for long-term engine performance.

- While aluminum excels in lightweight durability, plastic/composite materials offer adequate strength at a lower cost point.

- On the other hand, traditionalists may appreciate the rugged durability of cast iron despite its heavier build.

Weight

- Weight plays a significant role in determining the agility and fuel efficiency of a vehicle’s engine system.

- Opting for an aluminum-based intake manifold can significantly reduce the overall weight of the engine assembly without compromising structural integrity.

- In contrast, cast iron may add weight but provides stability benefits that cater to specific performance requirements.

Cost

- Cost considerations are essential when selecting the right material for an intake manifold based on budget constraints and performance expectations.

- Aluminum intake manifolds may come at a higher initial cost but offer long-term savings through improved fuel economy and efficiency gains.

- Plastic/composite options present a more budget-friendly alternative without compromising basic functionality or reliability.

Common Issues and Solutions

Potential Problems

Leaks

- Leak issues in the intake manifold can lead to air escaping from the system, affecting the engine’s performance.

- To address leaks, inspect the connections thoroughly for any signs of damage or wear.

- Applying a sealant to the affected area can help prevent further leakage and restore optimal functionality.

Cracks

- The presence of cracks in the intake manifold can compromise its structural integrity, impacting airflow and fuel delivery.

- When dealing with cracks, consider professional inspection and repair services to ensure a lasting solution.

- In severe cases, replacement of the damaged manifold may be necessary to maintain engine efficiency.

Carbon buildup

- Carbon buildup within the intake manifold can obstruct airflow and disrupt the air-fuel mixture process.

- Regular maintenance, such as cleaning or using fuel additives, can help prevent excessive carbon accumulation.

- Implementing preventive measures will safeguard against potential performance issues caused by carbon deposits.

Troubleshooting and Fixes

Identifying symptoms

- Recognizing early warning signs is crucial in diagnosing intake manifold problems before they escalate.

- Look out for indicators like unusual engine noises, decreased power output, or irregular idling patterns.

- Conducting routine inspections can aid in promptly identifying and addressing emerging issues.

Repair techniques

- When addressing intake manifold concerns, follow recommended repair procedures provided by automotive experts.

- Utilize appropriate tools and equipment to disassemble, inspect, and repair damaged components effectively.

- Seek professional assistance if unsure about specific repair techniques to avoid exacerbating existing problems.

Preventative maintenance

- Establishing a regular maintenance schedule is key to preventing potential intake manifold issues.

- Inspect the manifold system periodically for any signs of wear, leaks, or contamination.

- Adhering to manufacturer guidelines for maintenance intervals will prolong the lifespan of your intake manifold.

Case Study: A Practical Example

Real-world Scenario

Description of the issue

A Project Stork Porsche faced a perplexing challenge with its engine performance. Mechanics discovered irregularities in the air-fuel mixture distribution, leading to suboptimal combustion efficiency. The root cause was traced back to the intake manifold, where inconsistencies in airflow dynamics disrupted the engine’s operation.

Steps taken to diagnose

- Conducted a thorough inspection of the intake manifold structure and components.

- Utilized diagnostic tools to analyze airflow patterns and identify potential obstructions.

- Implemented pressure tests to assess the integrity of the manifold under varying operating conditions.

- Collaborated with engineering experts to simulate airflow simulations and pinpoint design flaws affecting performance.

Solution implemented

- Engineers redesigned the intake manifold geometry to enhance air distribution across cylinders.

- Optimized runner lengths and plenum volume for improved volumetric efficiency.

- Utilized advanced materials to reduce turbulence and enhance in-cylinder flow characteristics.

- Implemented CFD analysis for precise tuning of the new intake manifold design.

- To summarize, the blog explored the intricate components and functions of intake manifold connections, shedding light on their pivotal role in engine performance optimization.

- Understanding the nuances of intake manifold connections is crucial for enthusiasts and beginners alike, offering insights into enhancing engine efficiency and power output.

- Readers are encouraged to apply the knowledge gained from this guide to delve deeper into the fascinating world of automotive engineering.

- Werkwell welcomes your feedback and questions as you embark on your journey to unravel the complexities of intake manifold connections.

Post time: Jun-26-2024